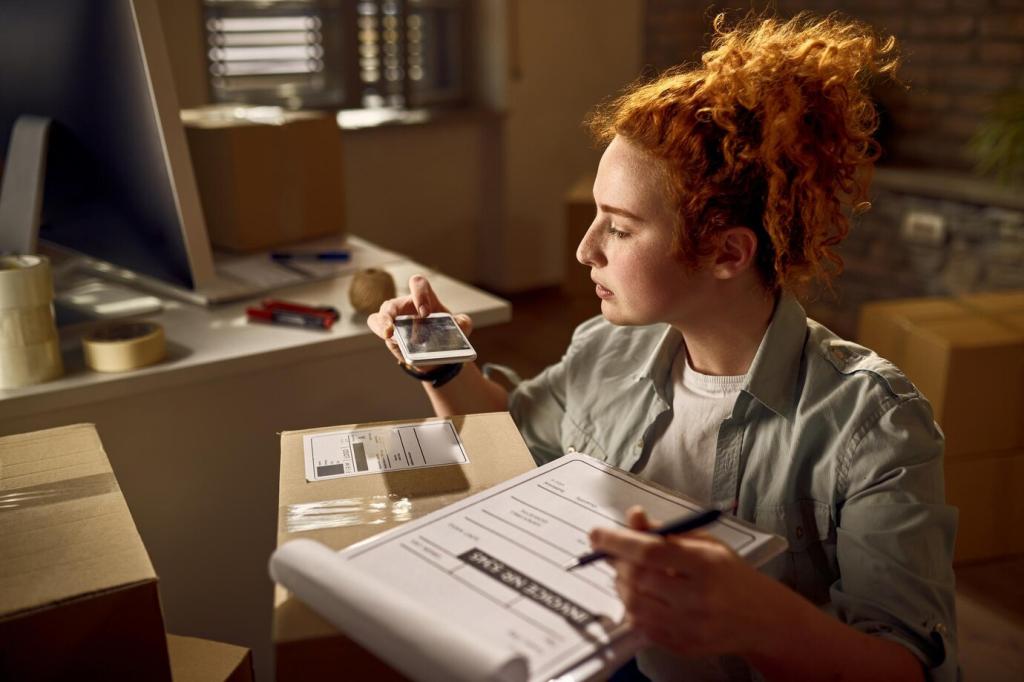

Forecasting and Replenishment That Actually Works

Start with proven models, then layer promotions, weather, events, and merchandising insights. An outdoor retailer paired ARIMA with event calendars and recovered 18% lost sales from festival spikes. Share what external signals move your demand most.

Forecasting and Replenishment That Actually Works

Use service level targets and variability-based buffers. Recompute frequently as volatility changes. When a supplier’s reliability slipped, dynamic safety stock cushioned stockouts without ballooning inventory. Subscribe for our parameter tuning guide.