What Is an Automated Inventory Management System?

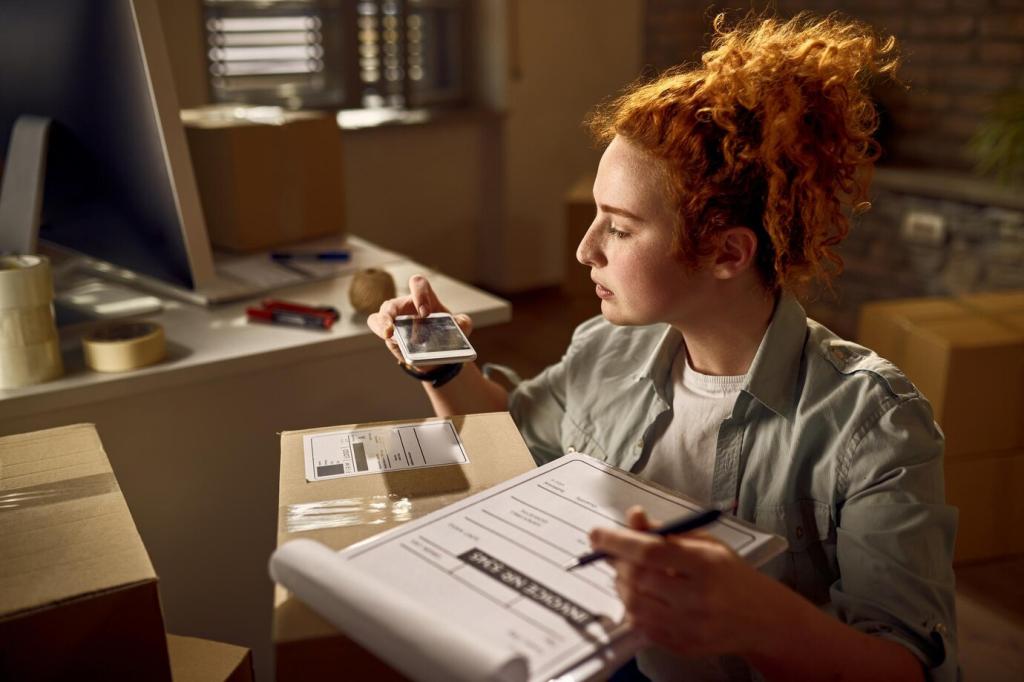

Barcodes, RFID, scanners, mobile apps, IoT sensors, and cloud software collaborate to track items from receiving to fulfillment. Automation standardizes transactions, timestamps movements, and reconciles counts so people focus on decisions, not repetitive data entry.

What Is an Automated Inventory Management System?

By replacing handwritten notes and memory with scans, validations, and system prompts, automated inventory management systems cut mis-picks, shrink, and stockouts. Managers trust dashboards because every adjustment is traceable, reviewable, and tied to a specific user action.